MECHANICAL

ENGINEERING

The Department of Mechanical Engineering at NIT Polytechnic, Nagpur, is dedicated to developing well-rounded engineers who are both technically skilled and socially responsible. Established in 2009, the program started with an intake of 60 students, which was expanded to 120 students in 2011-2012 to accommodate growing interest. The department proudly holds NBA accreditation, a testament to its commitment to quality education, valid until 2024-2025. Our highly qualified and dedicated faculty members ensure exceptional teaching and student development. Additionally, the department features state-of-the-art laboratories and workshops that provide practical training, aligned with and exceeding the MSBTE curriculum. Notably, we have industry-sponsored facilities such as the “Pravinya” Lab and the “Mechatronics” Lab, funded by AICTE under the MODROB scheme, which further enriches our students’ learning experiences and prepares them for successful careers in the field.

Vision

Emerge as a premier department to produce finely skilled mechanical technologists.

Mission

M-1. To inculcate excellent Mechanical Engineering knowledge andskills to increase employability and sustainability.

M-2. To provide quality education based on recent industrial requirements in the field of Mechanical Engineering.

M-3. To undertake skill enhancement training programs for students.

M-4. To impart social and professional ethics.

PROGRAMME EDUCATIONAL OBJECTIVES

Diploma Graduates of Mechanical Engineering Program shall,

PEO 1. Provide socially responsible, environment friendly solutions to Mechanical Engineering related broad- based problems adopting professional ethics.

PEO 2. Adopt state- of-the-art Mechanical Engineering broad – based technologies to work in multi-disciplinary work environments.

PEO 3. Solve broad – based problems individually and as a team member communicating effectively in the world of work.

PROGRAMME SPECIFIC OUTCOMES

PSO 1. Modern Software Usage: Use latest Mechanical Engineering related software for design , drafting, manufacturing , maintenance and documentation of mechanical engineering components and processes.

PSO 2. Equipment and Instruments: Maintain equipmentsand instruments related to Mechanical Engineering.

PSO 3. Mechanical Engineering Processes: Manage Mechanical Engineering processes by selecting and scheduling relevant equipments, substrates, quality control techniques and operational parameters.

About Department

- Year of establishment-2009 (First shift)

- Year of establishment-2012 (Second shift)

- Intake capacity – 120 per shift

- Approval from

- AICTE Approval No. – No.F.22-2760/2008(DIP ENGG) dt. 29-06-2009

- DTE Approval No. – No.10/AICTE/DIPLOMA/APPROVAL/2009/472 dt.26-08-2009

- Maharashtra Government Approval No. – No.Approval-2009/(304/09)TE-5 dt. 30-06-2009

- Affiliated to Maharashtra State Board of Technical Education, Mumbai. (MSBTE) – MSBTE / D-53 / AC / 0015 dt. 21-07-2015

Strength Of Department

- Excellent and Experienced Teaching Faculty.

- Excellent Academic result.

- Well equipped laboratories.

- Student participation in Extra Curricular activities.

- 100% Placement.

- Regular Industrial Visit.

- Campus interviews.

- Regular classes facility for Failure Students.

- Seminar from Experts from renowned industry.

- Developing Programming skill by conducting vocational Training Programme for J2EE,J2ME,Android,PHP ,CCNA and Computer repairing and Troubleshooting workshop.

- Developing practical skill by industrial Training programme, workshops and industrial Visits.

Carrier Prospectus in

Mechanical Engineering

Diploma course in Mechanical Engineering lays emphasis on manufacturing power Plants Automobile and Design Industries. Students after completion of this diploma programme can work in inspection, Quality Control, Maintenance and Production shops and Industrial Engineering Department in industries all government and semi government departments.

Student after passing out may join industries such as Mahindra, FACOR, TAL Manufacturing, CEAT Tyres, Kinetic Gears, BOSCH, L&T, Maruti Udyog, ESSAR etc. The students also have enough scope to start their own enterprise in many sectors like producing service & manufacturing facilities as well. Moreover students can join public sector too. Students can work as junior engineer at Government of India’s MINI-RATNA and MAHA-RATNA enterprises like BHEL, NTPC, OIC, SAIL, WCL, ONGC, HPCL, ordnance factory, DRDO, ISR

ACTIVITIES AT ME

Prof. Rajkumar C. Wadbudhe

Head of Department, Mechanical Engineering

NIT Polytechnic, Nagpur

HOD MESSAGE

Dear Students, Parents and Visitors, Welcome to the Department of Mechanical Engineering at NIT Polytechnic, Nagpur. Since our establishment in 2009, we have been dedicated to nurturing technically competent and socially responsible engineers ready to make meaningful contributions to society. We provide a holistic education that extends beyond academics, equipping students with essential soft skills, personality development, and communication abilities through specialized programs, including spoken English, aptitude training, and mock interviews. These initiatives ensure our graduates are well-prepared for the modern workforce. To enhance employability, we maintain strong industry collaborations, offering practical training in our industry-supported laboratories. Our Mechatronics and Power Engineering Labs, funded by AICTE under the MODROB-POL scheme, provide cutting-edge facilities for hands-on learning. With experienced faculty, advanced infrastructure, and an industry-focused curriculum, we are committed to empowering students for successful careers and meaningful contributions to society. We look forward to witnessing our students grow into professionals who embody excellence, integrity, and innovation.

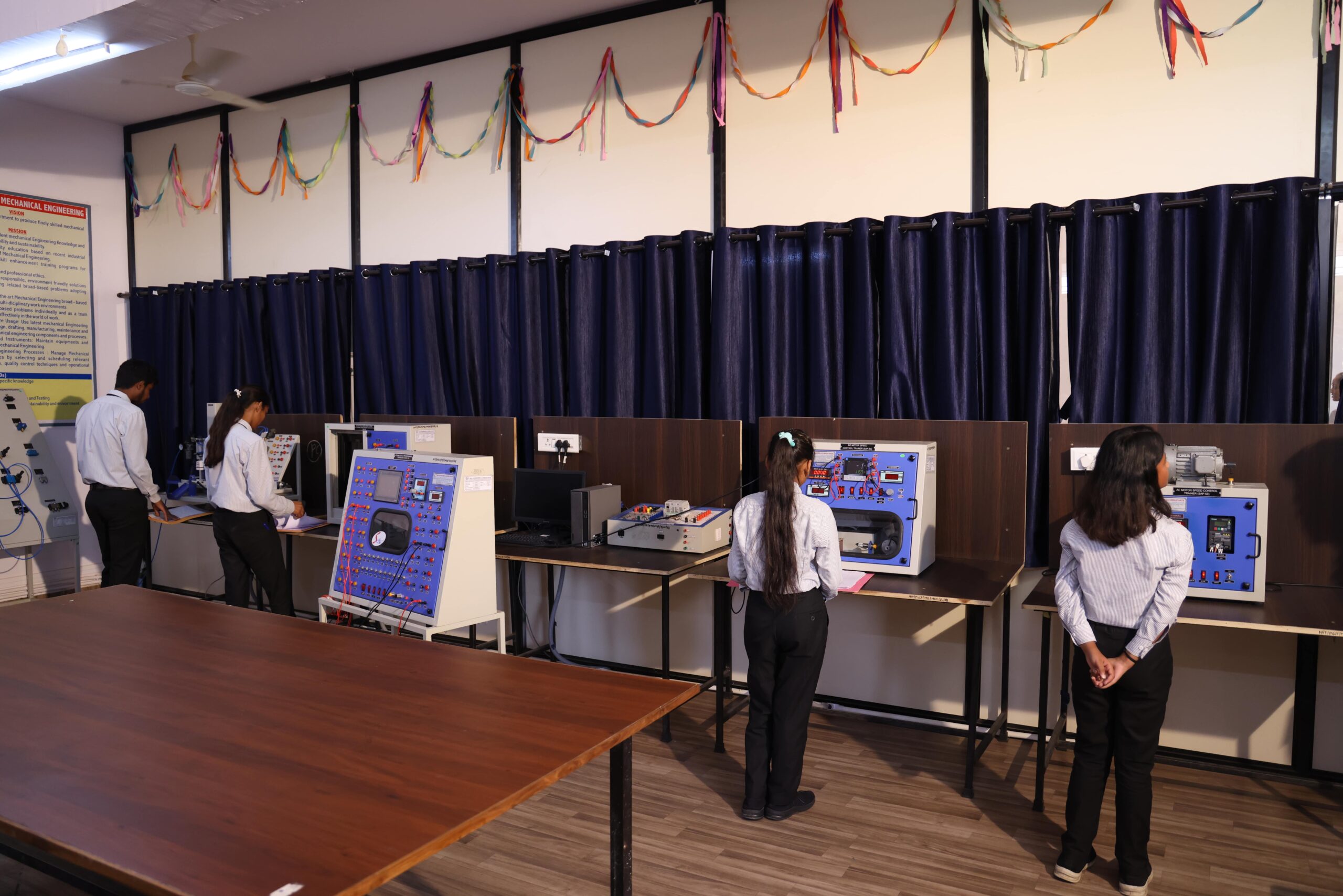

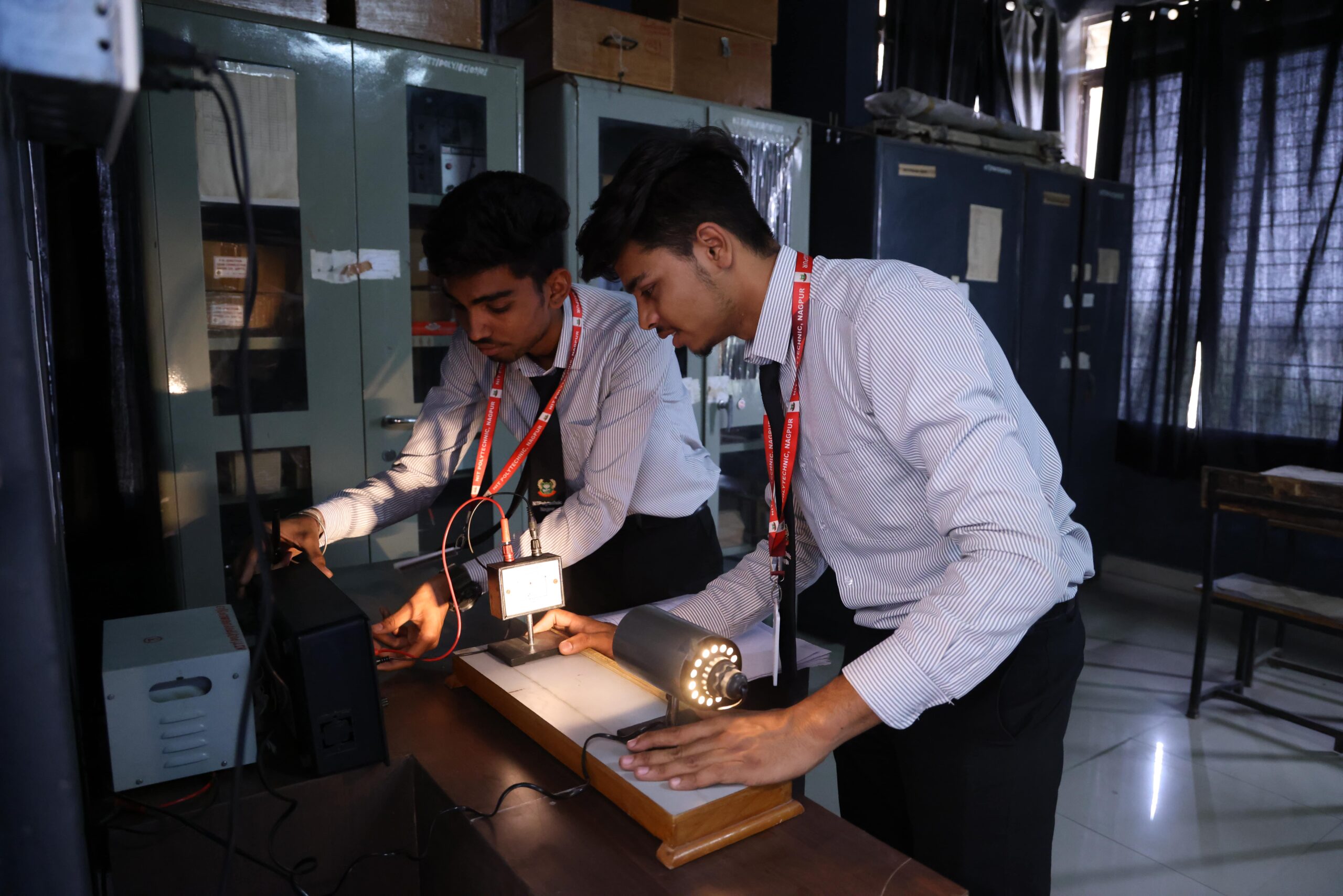

DEPARTMENT LAB

LAB IMAGES

Details

Mechanical engineering department of NIT POLYTECHNIC is equipped with state of art laboratory and complete setup of tools and equipments required to enhance technical knowledge of students.

Various laboratories are maintained under department as per the AICTE norms

FLUID MECHANICS & MACHINARY LABORATORY

The Fluid Mechanics & Machinery Lab helps students understand fluid properties, flow behavior, and hydraulic machinery used in various engineering applications. The lab enables students to analyze fluid flow dynamics, pressure losses, and energy conversion in hydraulic systems.

Major Equipment:

- Bernoulli’s Test Rig

- Pelton Wheel Test Rig

- Centrifugal Pump Test Rig

- Venturimeter Test Rig

- Hydraulic and Pneumatic Test Rig

Lab Incharge : Mr. Rakesh Ahirkar

Approximate Cost: 5 to 6 Lakh

Computer Engineering

The Computer Engineering Lab in Mechanical Engineering provides students with hands-on experience in computer-aided design, drafting, and modeling used in modern engineering industries. It enables students to create 2D drawings, 3D models, and simulations using industry-standard software like AutoCAD, CREO, and SolidWorks.

Lab Incharge: Mr. Gaurav Umathe

Approximate Cost: 8 to 10 Lakh

CNC Lab

The CNC Lab is a specialized facility designed to provide students with hands-on experience in CNC Machie and CNC Programming. This lab helps students learn about CNC programming, machine operations, and modern manufacturing techniques used in industries.

Lab Incharge: Mr. D. R. Rangari

Power Engineering and RAC Lab

The Power Engineering & RAC Lab provides hands-on experience in equipment related energy conversion, thermodynamics, power generation, and cooling systems. It covers IC engines, steam turbines, compressors, and refrigeration cycles, essential for industries like power plants, HVAC, and thermal engineering.

Major Equipment:

- Computerized IC Engine Test Rig

- VCRS Test Rig

- Water Cooler Test Rig

- Air Conditioner Test Rig

- Air Compressor Test Rig

Lab Incharge: Mr. Ritesh Harode

Approximate Cost: 10-12 Lakh

Metrology and Measurement Lab

The Metrology and Mechanical Engineering Measurement Lab focuses on precision measurement, quality control, and calibration techniques essential for manufacturing and engineering industries. The lab helps in understanding dimensional accuracy, tolerance analysis, and surface finish evaluation, ensuring high-quality production standards. This lab is crucial for careers in quality assurance, product inspection, and industrial metrology.

Major Equipment:

- Optical Profile Projector

- Tool Maker’s Microscope

- Vernier Caliper

- Micrometer

Lab Inchrage : Mr. Mangesh Dharme

Automobile Engineering and TOM Lab

The Automobile Engineering Lab provides hands-on training in automotive systems; and Subsystems. The lab enables learners to observe the construction and working of various components of automobile vehicles.

Major Equipment:

- Cut Section model of Gearbox

- Cut Section model of Differential and Axle

- Model of Steering

- Model of Brake

Lab Inchrage: Mr. Ashish Umarkar

Funded Lab at ME

Industry Sponsored Lab “PRAVINYA”

The “Pravinya” Lab is an industry-sponsored laboratory established in collaboration with John Deere Tractors Pvt. Ltd. to provide students with hands-on experience in tractor mechanics, and power transmission systems. This lab is a specialized training center where students can explore construction and working technology of modern tractor, and its components.

Major Equipment:

- Cut Section working model of Tractor

- Cut Section working model of Engine

- Cut Section working model of Transmission Sysetem.

Lab Inchrage: Mr. Prashant Rahate

Mechatronics Lab

The Mechatronics Lab combines mechanical, electrical, and automation technologies, offering students hands-on experience in industrial automation and control systems. It is equipped with PLC programming trainers, servo motor controllers, pneumatic and hydraulic trainers, and automated control systems, enabling students to develop expertise in sensor integration, motor control, and process automation, which are vital for smart manufacturing and modern industries. This laboratory is funded by AICTE under the MODROB-POL Scheme, enhancing its capabilities with advanced technology and equipment.

Lab Incharge: Dr. Pooja Jaiswal

Approximate Cost:12-14 lakh

Workshop

1. Machine Shop

The Machine Shop is one of the most fundamental labs in mechanical engineering, where students learn machining operations such as turning, milling, drilling, and shaping. This knowledge is crucial for manufacturing and production industries.

Major Equipment:

- Lathe Machine

- Milling Machine

- Drilling Machine

Approximate Cost: ₹10-15 Lakhs

Instructor: Mr. Harshal Zodape

2. Fitting Shop

This lab provides training on basic hand tools and fitting techniques. Students develop skills in marking, cutting, and assembling metal components, which are essential for manufacturing and maintenance.

Major Equipment:

- Bench Vice

- Files

- Hacksaw

- Surface Plate

- Height Gauge

Approximate Cost: ₹3-5 Lakhs

Instructor: Mr. Sanjay Dhamedar

3. Carpentry Shop

The Carpentry Shop teaches students about woodworking, measurement, and cutting techniques used in the construction and furniture industries.

Major Equipment:

- Jack Plane

- Chisel

- Tenon Saw

- Rib Cut Saw

- Bench Vice

Approximate Cost: ₹2-4 Lakhs

Instructor: Mr.

Nestled in Nature, Inspiring Minds –

A Campus Where Learning Meets Serenity

Our sprawling 26-acre campus features modern academic facilities, lush greenery, and a wide range of amenities, including state-of-the-art classrooms, a comprehensive library, advanced IT infrastructure, extensive sports areas, and dedicated spaces for student activities and relaxation